With a cutting speed up to 600mm per second (24m/min) over an active cutting area of 2180mm x 3860mm and maximum material thickness of 135mm, the TEXCEL EXR3000 router system is perfect for cutting machinable materials such as;

- Aluminium Sheet (up to 50mm thickness)

- Aluminium Composite Panels (Alucobond etc)

- Non Ferrous Metals (Copper, Bronze, Brass etc)

- Equitone

- MDF, plywood, hard and soft woods,

- Industrial plastics and extruded acrylics

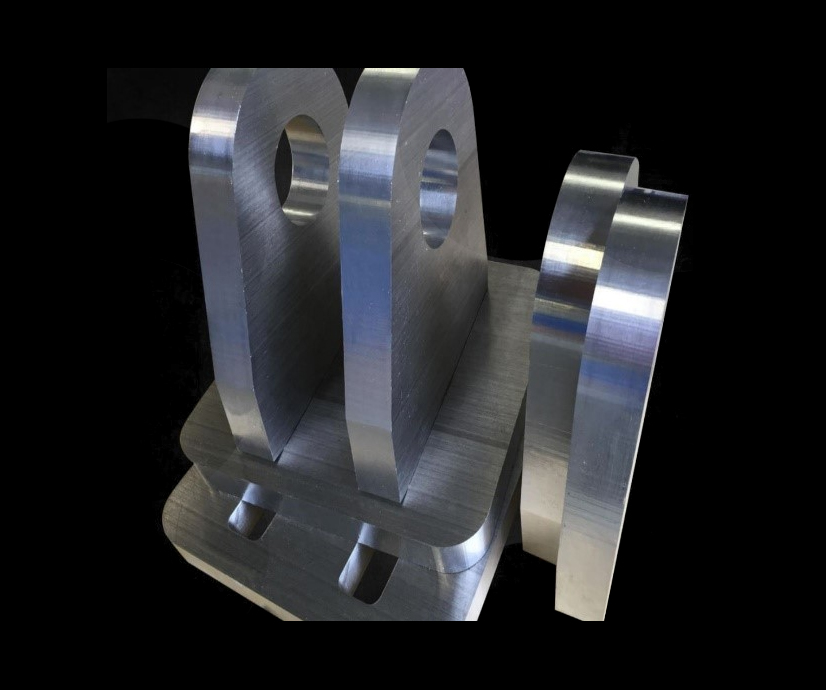

The advantage that CNC Routing has over other cutting methods (such as laser cutting and plasma cutting) is that the edges are much smoother so sharp edges and burrs can be avoided. The depth is also controllable. This enables us to cut grooves and add shoulders, as well as perform countersink operations.

How to get started? First, we draw our design geometry in AutoCAD, and then export them to a tool path program. Alternatively, if you have your drawings already in CAD, then forward us the dxf file of the panels you need cut. The CAD file may contain all the panels you need on one drawing, or separate files for each part. After import, the parts are nested onto a plate, to ensure minimal material waste. Finally, the program is built, and subsequently sent to the router for cutting.

Don’t have a CAD file only an image or idea? Call or email Perfmet Engineering today and our in-house sales team and designers will work with you to fulfill your projects needs.